Below is a little bit of information about how we make MouCo Cheese.

…with some pictures of our toys, of course.

If you have any questions, please feel free to reach out and contact us.

Chuck the milk truck parked in front of MouCo on a sunny summer day, showcasing the warmth and charm of our cheese-making operation.

MouCo's Chuck the Milk Truck

Chuck the Milk Truck at La Luna

Panoramic view of DFA truck and Chuck the MouCo milk truck at sunrise, with the helpful DFA driver assisting with milk loading.

Chuck, MouCo's trusty milk truck, collecting fresh milk at La Luna dairy farm under a beautiful sunrise.

Chuck waiting his turn

Precise measurement of milk at La Luna dairy farm, ensuring an accurate pickup for MouCo Cheese Company.

Bringing in the Milk

Our cheese-making adventure begins with the freshest, most delicious milk from the local cows grazing along the picturesque Colorado Front Range. Meet Chuck, our trusty milk truck, who embarks on a scenic 11-mile journey from our cheesery to the dairy farm to in the early morning, a few times a week. Chuck’s mission: to bring raw milk, the heart and soul of our cheese.

To guarantee our milk is top-notch, we put it through a rigorous gauntlet of tests. We’re talking about examining every drop for the perfect blend of proteins and fats to ensure our cheese is creamy and dreamy every time. Cleanliness is next to cheesiness, so we also check for any unwelcome guests like antibiotics. Only the finest, purest milk makes the cut, setting the stage for the magic that is MouCo cheese.

A detailed close-up of the electronics cabinet on the milk pasteurization system at MouCo Cheese Company.

The milk pasteurization system for MouCo Cheese, freshly arrived and waiting in the parking lot before being installed in the facility.

Testing of the HTST milk pasteurization system by the Colorado State Health Board, observed by MouCo employees and trainees.

Pasteurization

Next up, it’s time for our milk to hit the heat in the most delightful way. We use our honky-dory HTST (High Temperature Short Time) pasteurizer to meet the top-notch standards of the Colorado State Health Department. This crucial step zaps any pesky pathogenic bacteria, making the milk safe for both sipping and cheese-making. But wait, it gets even better! Our snazzy system recycles much of the heat it uses, making it a whopping 70% more efficient than old-school vat pasteurizers. Talk about a win-win!

After this whirlwind of warmth, our milk deserves a little R&R. We let it take a well-earned break overnight to “mellow out,” because even the busiest milk needs a moment to chill before transforming into scrumptious cheese.

An employee carefully watches over the start of a batch of MouCo cheese, monitoring temperature and adding ingredients.

Close-up of a MouCo milk tank valve with the final drips of milk as the tank is prepared for cleaning.

Careful weighing of culture for a new cheese batch, ensuring precise measurements and sanitary handling.

Cheese Making Begins

Now, the real magic begins! We gently warm the milk to a cozy, body temperature and introduce our special bacterial cultures. These tiny heroes feast on milk sugars (lactose) to create a symphony of acids, aromas, and flavor compounds. Depending on the type of cheese we’re crafting, we mix and match different cultures, each with its own unique flair.

After a brief interlude, it’s time for the grand entrance of the enzyme. We add a touch of 100% natural veal rennet to the mix. Though we use it sparingly—just a whisper at 0.0000375 grams per cheese—this mighty enzyme works wonders, transforming the milk into a solid mass known as curd. This magical moment is called curding, or setting.

Within about an hour, our curd reaches the perfect consistency, ready for its next adventure: being cut into smaller, bite-sized bits, setting the stage for the next step in our enchanting cheese-making journey.

...back in the day...~2004

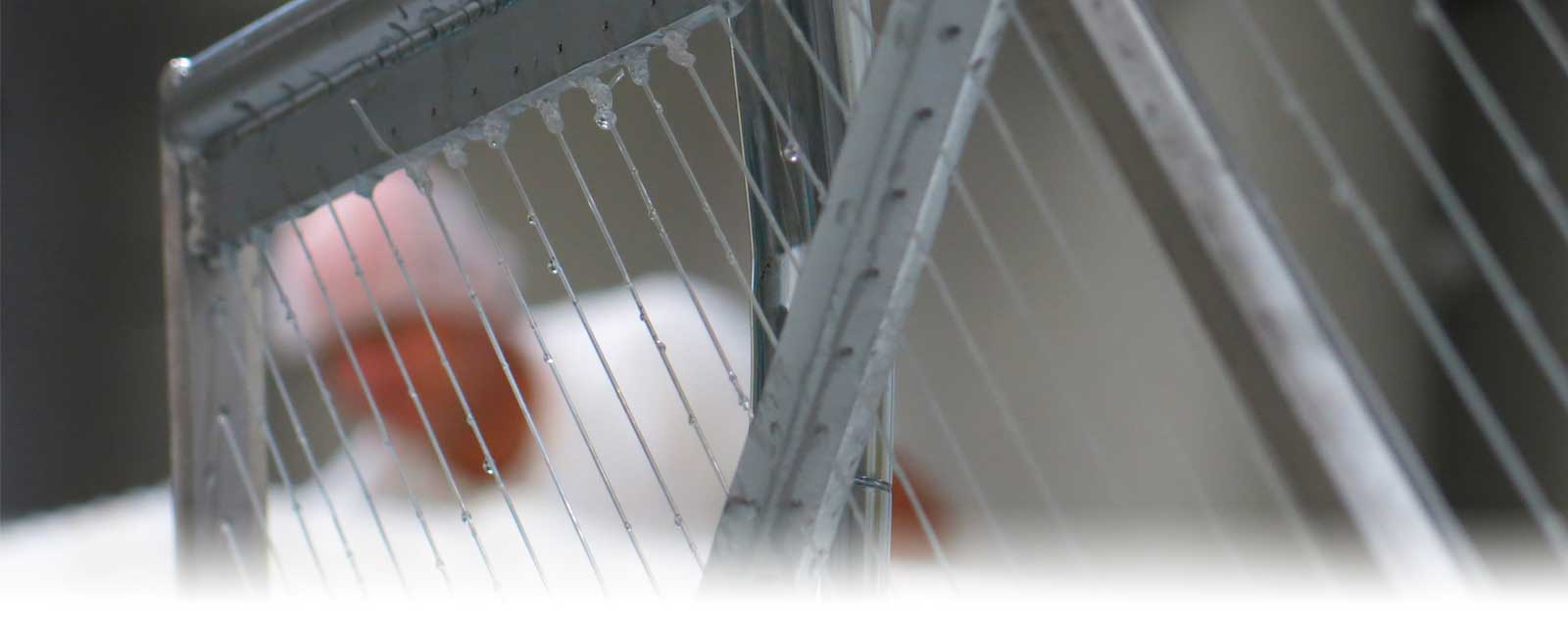

A close-up of the cheese cutting harp, an essential tool in the MouCo cheese-making process.

A close-up view of the curd cutting process, showcasing the precision involved in MouCo's cheese-making.

A close-up of a cheese harp with a faded bottom, featured on the MouCo website to illustrate the cheese production process.

Cutting

Now it’s time for the curd to take center stage in its next act: cutting. We slice the curd into dice-sized cubes, allowing the water, or rather the whey, to start its journey out of the curd. Over the next half hour, these cubes begin to contract, gently squeezing out even more whey.

But whey is no simple bystander—it’s mostly water, yes, but it’s also packed with proteins, minerals, and leftover carbohydrates. This process is crucial as it sets the stage for our curd to transform into the delectable cheese you know and love.

Close-up of form-filling funnels guiding cheese curds into individual molds to create perfectly sized cheeses.

A close-up view of the end of the filling shoots, capturing the precision and flow during MouCo's cheese filling process.

The KBA chutes system in action, connecting the cheese-making vessel with forms to fill 360 cheeses simultaneously.

Forming

With our cheese forms ready to embrace their tasty creations, the cheese maker gives the curds and whey one final, loving stir. Then, the whole kit and caboodle gets tipped out of our fancy KBA (that’s “tipping vessel” in German, for those keeping track) into block forms. In these forms, the curds come together, snuggling up to take the shape of the cheese, all while continuing to drain whey until they reach the perfect size.

Each form holds 45 of our delightful cheeses, and with each tip of the KBA, we fill eight of these forms to the brim. To ensure every bit of cheese drains evenly, we flip the forms a few times, giving our future fromage the perfect start to their flavorful journey.

~2004 ...back in the day with Josh...Salting...

Salting

As dawn breaks, it’s time to give our cheese a sprinkle of something special. The next morning, we salt the cheese, which helps slow down the acidification process and perfectly balances the flavor. This crucial step also lays the foundation for that delicious, edible rind.

Once salted, our cheeses are carefully transferred to stainless steel racks, ready for the ripening stage. Here, they will transform, developing their rich flavors and textures, inching closer to becoming the MouCo masterpieces you can’t wait to enjoy.

Close-up of MouCo soft-ripened cheese immediately after emerging from the salt basin, ready for the ripening room.

Racking MouCo Cheese

Racking MouCo Cheese

MouCo Camembert cheese resting on stainless steel racks, freshly out of the brine bath.

MouCo ColoRouge cheese rounds sitting on stainless steel racks, just before wrapping, with a soft fade around the image border.

MouCo Camembert cheese wheels resting on steel racks, captured with a soft fade around the edges of the image.

A close-up of a rack of MouCo ColoRouge cheeses freshly inoculated, showcasing the cheese’s vibrant orange rind.

Cheese Ripening

Now, the racks are whisked away to our special ripening room, where the real magic unfolds. For the next few weeks, we keep a close eye on the humidity and temperature, ensuring everything is just right. During this time, a beautiful surface flora of white mold begins to bloom on the outside of the cheese. This marvelous mold doesn’t just protect the cheese—it enhances the flavor and kickstarts the aging process.

As soon as the cheese is fully enveloped in this protective moldy embrace, it’s ready for its final transformation: packaging. This is the moment our cheese has been waiting for, preparing to make its grand debut on your table.

A throwback to 2008 at the MouCo cheesery, where kids joined in to help make the original boxes that held the cheese.

~2015 ...Wrapping Cheese

Packaging

Our cheese gets dressed for success in a special cheese paper imported all the way from Memmingen, Germany—Birgit’s charming hometown. This extraordinary paper allows the surface cultures on the cheese to breathe, taking in oxygen and releasing CO2 to stay alive and thriving.

This living, breathing process lets the cultures continue their work, breaking down the protein structure and softening the cheese over the next few months. It’s like a cozy little blanket that helps our cheese mature gracefully, ensuring it remains deliciously delightful until it reaches your table.